Economic uncertainty, supply-chain disruptions, and a shortage of skilled tradespeople. While it is undoubtedly a challenging time for the construction industry, Andrew Miller, our own procurement and materials manager, says that despite the known volatility, it’s business as usual for many retailers.

Although retailers are trying their hardest to move on, the impacts of COVID are still rattling consumers. Political unrest, astronomical inflation, and slow lead times have made resources more difficult to secure. However, Andrew says despite a perceived economic slowdown and logistic challenges, many retailers are in post-COVID growth mode. “The majority want to go hard with designing, constructing, and opening stores.” Meanwhile, there are some brands that are taking more of a wait-and-see approach, he says.

Andrew’s expertise lies in both environmental design and materials sourcing, which gives him a solid understanding of all the forces at play when it comes to bringing a design project to life. From flooring to facades, Andrew and his team procure all the materials needed to build a modern store. We recently sat down with him for some insider insights about the current state of retail construction and some tips from the trenches for anyone considering a building project right now.

Tip 1: Keep Calm + Communicate

Other issues impacting materials right now include difficulty obtaining the ingredients used to make materials like powder coatings for fixtures. Even when materials are readily available, it can take an exceeding amount of time to get them to where they need to be, causing headaches for retailers, designers, and general contractors. Thankfully, Andrew says, continually communicating the situation with clients is key to their understanding of the challenges facing the building materials and construction industry today.

“Prices have increased a great deal for materials. Even though we create a timeline, the project can run longer than anticipated because of delays and so forth,” says Andrew. “Following up and communicating regularly is key, not only with clients but also with suppliers and contractors.” The process can test even the calmest of procurement managers. “It can be challenging not to get frustrated. Clients have been understanding overall, but, like us, most clients are also very eager to get the project done.”

Tip 2: Tweak the Plan + Find Workarounds

Innovation often comes from working within restraints, and Andrew welcomes this kind of progress within his industry. By finding workarounds within the design, using alternative materials, and tweaking construction plans, Andrew finds answers to project problems that would otherwise cause delays.

“Sometimes there are answers. We can work within the design concept to choose materials that have a shorter lead time,” he says. When it comes down to it, if a timeline is at risk, another material may have to do. “We have to work around it and find another source. It’s all part of the gig. These times are challenging, and it helps us to think outside the box about other directions we can take. It’s important to stay nimble and adaptive to meet brands’ needs.”

Tip 3: Work Ahead

Andrew says that it helps to get as much construction done ahead of time in-house. “When we build on-site and in layers, it helps keep things on track,” he says. Working ahead as much as possible can be a critical timesaver. When necessary, utilizing layered construction practices allow the team to build onto what they have as materials become available.

Tip 4: Keep it Local

Nearshoring is the new buzzword when it comes to sourcing—and with good reason. The movement of sourcing closer to home shortens lead times, lowers costs, and reduces carbon emissions. We can expect to see new, closer, manufacturing hubs dedicated to meeting U.S. and European demand. A Business of Fashion annual survey of chief purchasing officers in North America indicates that more than 75% expect to increase the share of sourcing from Central America in 2023 and more than 35% expect to increase the share from Mexico.

Another trend Andrew welcomes is local sourcing. His team calls on local suppliers to obtain materials and get the work done more quickly rather than waiting for a shipment to come for them to get started. “Sourcing locally and working with local suppliers on our projects has helped us weather the storm,” Andrew says.

Tip 5: Work Only with Trusted Partners

There’s also another issue at play within the trades industry right now—they are just too busy. “Jobs in the trades are in high demand, and an issue is holding people accountable when they can’t manage their workload,” Andrew says. Another challenge is the amount of effort it takes to build a great experience. “That’s why it is critical to call on only the ones you have a trusted partnership and working relationships with—and trust to get things done correctly.”

Tip 6: Slow Down + Think Sustainably

“I would love to see more sustainable materials used, but really, we are all just moving very fast and trying to get the materials,” says Andrew. “Some clients really want to incorporate sustainability where they can—but it’s usually in flooring material or eco-friendly fabric, not so much with building materials.”

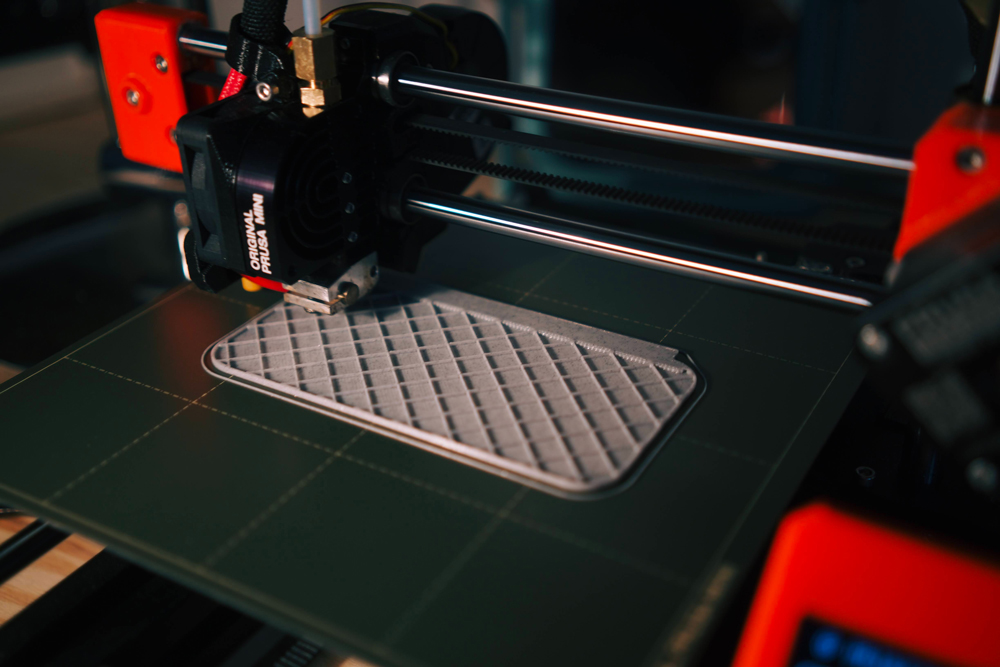

While his team has created fixtures made of engineered plywood and he sees clients using sustainable materials to craft their mannequins. “I hope when the industry slows down (in a good way), we will be able to focus more on using the sustainable products of the future—fixtures, building materials, flooring, and even playing around with 3D printing to make small tables and stuff,” he says. “It’s the future. I hope we can use it to think bigger.”